"There were very few regulations - public regulations, employee safety regulations - that businesses had to follow. Puleo described how the case's ruling would completely change the relationship between business and government. There were over 1,000 witnesses called in this case, 1,500 exhibits, and really kind of sets the stage for future class action lawsuits." "So really kind of a landmark, important case. "The first case in which expert witnesses were called to a great extent: engineers, metallurgists, architects, technical people," Puleo said. Immediately following the flood, 119 plaintiffs took up a civil lawsuit against U.S.

Rescue efforts continued for days, and cleanup took even longer. As it spilled out, it cooled down and thickened, trapping survivors in the mess. Two days before the accident, a new shipment of hot molasses had been added to the tank, so when it burst, the molasses inside might have been slightly warmer than the outside air. "You basically have a giant stack of something that’s really heavy and as soon as you remove whatever’s holding that - in this case, the walls of the tank - all of that is going to rush out, and a lot of that potential energy that you had from stacking this thing up really high is going to turn into kinetic energy.

"It’s mostly the density of the molasses, so how much it weighs, and how tall it is," explained Nicole Sharp, an aerospace engineer and science educator, who has studied the fluid dynamics of molasses. When the company received complaints that the tank was leaking, it painted the tank brown to disguise the leaks rather than repair them.īesides the structural aspects of the tank, researchers have explored how the scientific properties of the molasses itself explain why the flood was so destructive.Ĭredit Courtesy of Boston Public Library, Leslie Jones Collection Fire House No. Industrial Alcohol, the company that owned the tank, had rushed to build it, employing an overseer who was an expert in finance, not engineering. On top of that, it looks like the method that they used to make the rivet-holes - the way that they put the tank together in those days was by riveting, not welding - was substandard, and that that may have created small cracks, and on top of that, the steel that they used, although it was state-of-the-art of the day, we know today that it could be relatively brittle under certain circumstances." Whoever did the design failed to provide the adequate thickness of the steel. "No one knows exactly why it failed, but one thing is very clear: it was under-designed. Researchers like Ronald Mayville have been fascinated by this incident, studying the causes behind it as a phenomenon of science and engineering.

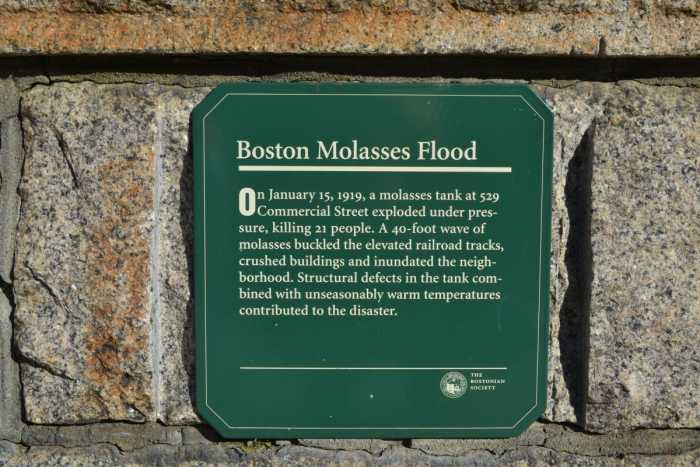

Howe and other sailors were some of the first people on the scene, helping with rescue efforts where they could.Ĭredit Courtesy of Boston Public Library, Leslie Jones Collection Site of Molasses Disaster showing lumberyard to left near Charleston Bridge. So two of us got a hold of his arm and pulled and unfortunately, we pulled his arm off." On a boat docked in the harbor, Howe witnessed the incident firsthand, as he recalled in a 1981 interview with the Stoneham Public Library: "We saw this big cloud of brown dust and dirt and a slight noise. And there was an arm sticking out from underneath the wheel of a truck. Harry Howe was on leave from the navy for the weekend when the flood occurred. And I’m talking injuries like broken backs, fractured skulls." "About 21 people die, 150 people injured seriously. "It collects and destroys buildings, people, domestic animals, stables - there are about 25 horses that are killed," Puleo explained. So on the day of the flood, despite leaks and groans, no one anticipated that the tank was about to burst, unleashing a 30-foot-high wave of 2.3 million gallons of molasses that would move 35 miles an hour down Commercial Street. It was very customary for children of the North End to go and collect molasses with pails."

"There were often comments made by people around the vicinity that this tank would shudder and groan every time it was full, and it leaked from day one. There were signs that the tank was faltering, but the people of the North End had gotten used to its instability. So there were deliveries all day long, this was a bustling, hustling kind of place." "Almost all of the shipping that left Boston to go up and down the East coast, to go to Europe, left from this site. "This was one of the busiest commercial sites in all of Boston," Puleo said. Credit Julia Press The view down Commercial Street.

0 kommentar(er)

0 kommentar(er)